For Pressing of Dental Ceramics and Lithium Disilicate

One of the major challenges in the laboratory daily work is the avoidance of error sources, which prevent

consistent results. More than 8 million press plungers sold in a few years provide evidence of the efficient

and safe processing of lithium disilicate pressed ceramics.

■ The use of disposable press plungers prevents a heat accumulation after the pressing process,

caused by the contact of the plunger with the lithium disilicate pressed ceramic

■ Does not require a separator when pressing lithium disilicate

■ Easy handling

■ No preheating

■ The cleaning of press residues is not necessary

■ Simply dispose of after use

Better Results when pressing Lithium Disilicate

Zubler® disposable plungers have convinced the users due to their advantages in terms of pressing

results, handling and profitability.

From the use of aluminum oxide plungers there result the greatest sources of error when processing pressed ceramics. They are jointly responsible for short pressings and cracking. Due to their unique material

components Zubler® disposable plungers prevent cracking in the transition zone between ceramic

and plunger.

No sticking together of the pressing unit with non-removed ceramic residues on the Alox plunger and no

conical plunger after repeated blasting.

You may also like…

-

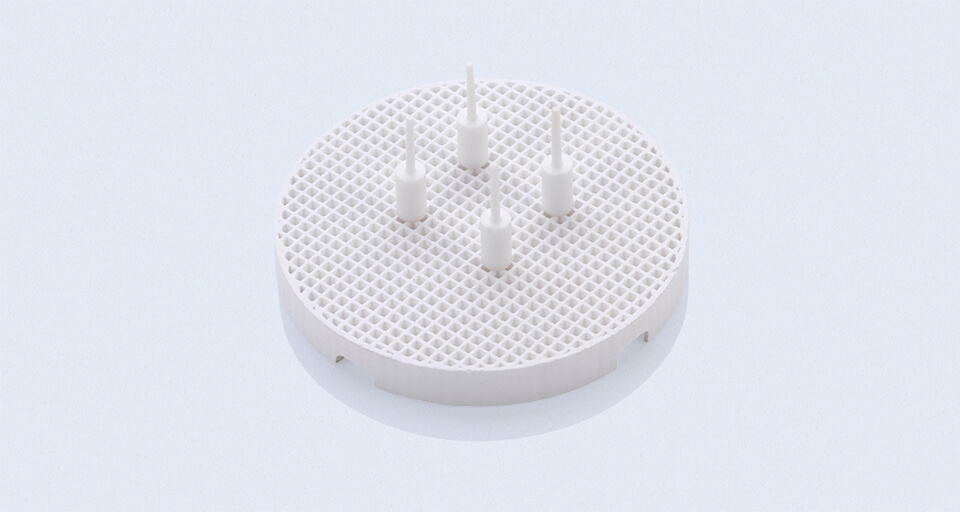

Honeycomb Stand

35,00 JOD -

Easy Fix

65,00 JOD -

Easy Grip

30,00 JOD